Harsh environment fiber diagnostics

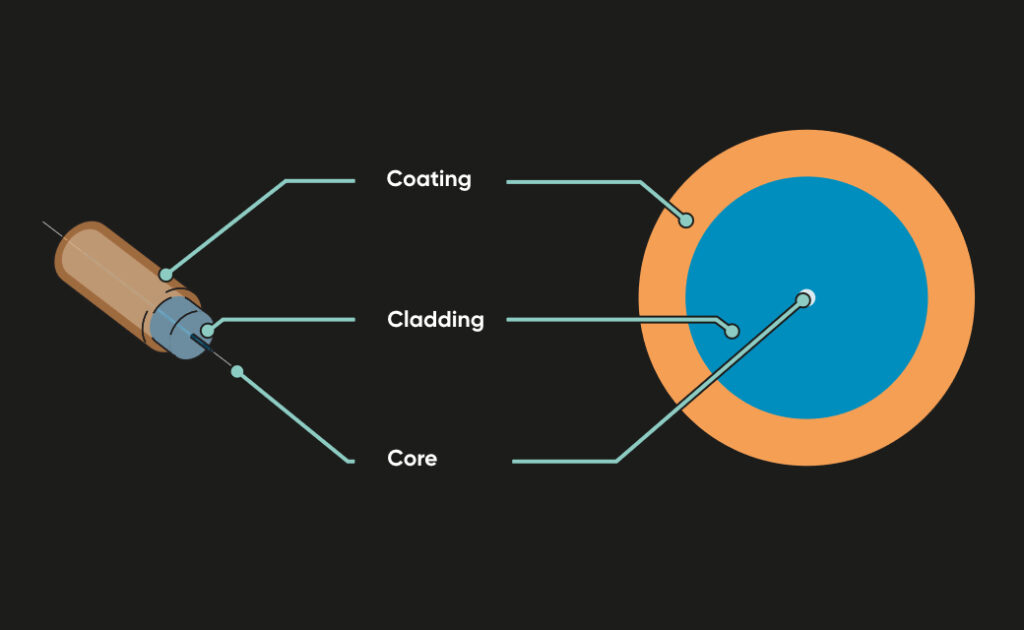

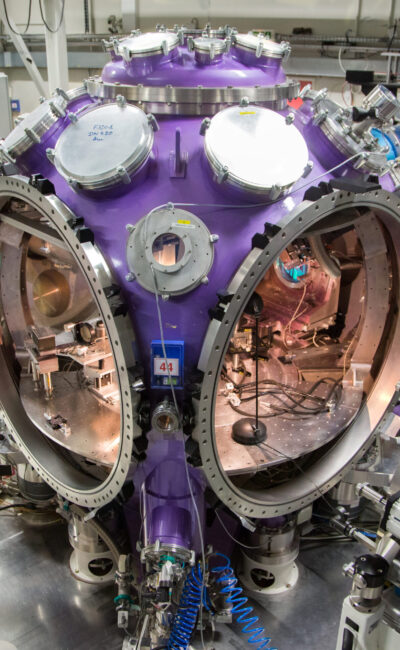

Harsh environments usually refer to extreme temperature and/or radiation level, and encompass environments such as nuclear facilities, high energy physics laboratories, and space. Leveraging decades of continuous improvements made on standard telecom fibers, specialty optical fibers are now widely used in harsh environments for data transmission, sensing or in-vitro diagnosis.

Optical fibers are well suited for operation in extreme temperatures and radiative environments as they benefit from a light weight and low volume, low loss and high bandwidth, an immunity to electro-magnetism, and an ability to operate under a wide temperature range. Exail is a designer and manufacturer of passive or active specialty fibers, offering virtually unlimited design possibilities and optimization for UV, visible or NIR wavelengths through the careful selection of raw material, dopants and doping profile.

Publications

-

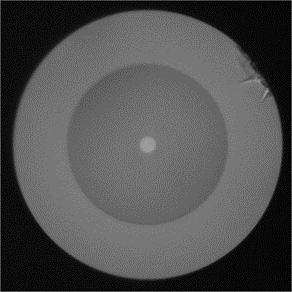

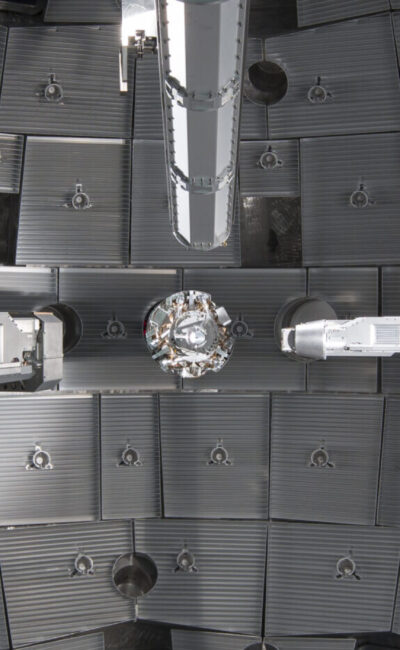

Phosphosilicate Multimode Optical Fiber for Sensing and Diagnostics at Inertial Confinement Fusion Facilities

IEEE Sensors Journal ( Volume: 22, Issue: 23, 01 December 2022)

https://ieeexplore.ieee.org/document/9934019 -

Overview of radiation induced point defects in silica-based optical fibers

S. Girard et al., Reviews in Physics (4) 100032, 2019.

https://doi.org/10.1016/j.revip.2019.100032 -

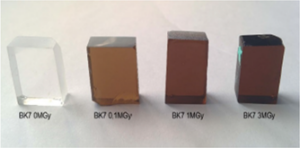

Combined effect of radiation and temperature: towards optical fibers suited to distributed sensing in extreme radiation environments

30th Conference on Radiation and its Effects on Components and Systems (RADECS 2019) – September 2019

Combined effect of radiation and temperature on the response of polyimide coated radiation hardened single-mode fibers is investigated in the context of distributed monitoring of large nuclear infrastructures. Radiation induced attenuation (RIA) is evaluated for doses ranging from 1 to 10 MGy(SiO2) and temperatures up to ~250 °C.

Learn more -

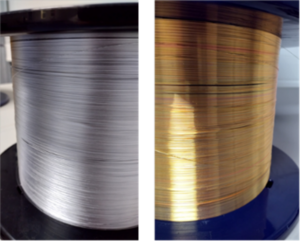

Radiation resistant single-mode fiber with different coatings for sensing in high dose environments

IEEE Transactions on Nuclear Science – 10 December 2018

A radiation single-mode optical fiber has been specifically developed for distributed sensing in harsh environments associated with MGy(SiO2) dose radiation. Different types of coating have been used: acrylate, polyimide, aluminum that allow extending the range of accessible temperatures up to 400°C…

Learn more -

Radiation hardened temperature measurement chain based on femtosecond laser written fbgs in a specific optical fiber

5th Workshop on Specialty Optical Fiber and Their Applications – October 2017

A radiation resistant temperature measurement chain based on femtosecond laser written FBGs is described. First results confirm a suitable design to withstand foreseen harsh nuclear envirnoment both in term of temperature and cumulated dose.

Learn more