High-Energy Laser Facilities

High-energy lasers are pulsed lasers with a high output pulse energy. They emit light pulses with 100 mJ or more of energy. When amplified, they reach far higher energies, up to multiple kilojoules or even megajoules. In conjunction with short pulse durations (nanosecond), high pulse energies imply rather high optical peak powers (a hundred of MW for 1 joule delivered with 10 ns). Fiber lasers are known to be the most efficient high-power laser technology demonstrated to date as they leverage extensive industrial development coming from the telecom rise.

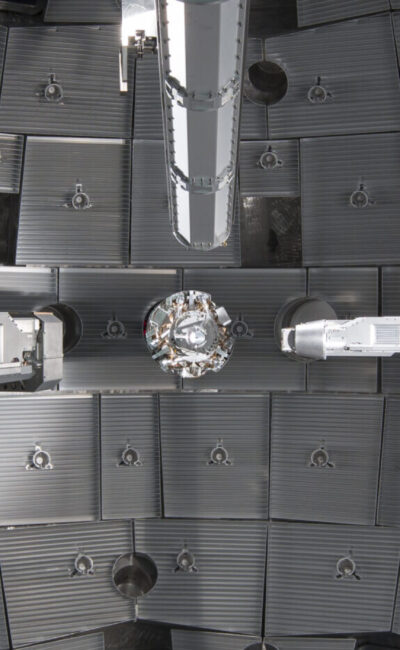

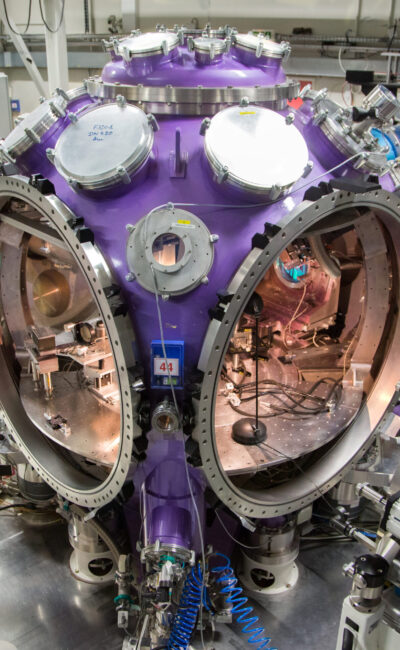

This page is about the application of high-energy laser in very powerful laser facilities, for inertial laser fusion or for research on light-matter interactions. With its radiation resistant (rad-hard) fibers and its integrated modulation solution based on lithium niobate (ModBox FE) for the temporal shaping, Exail is able to deliver two key components to this application. Major facilities (CEA-LMJ, LLNL-NIF) are among the customers of such cutting-edge technologies.

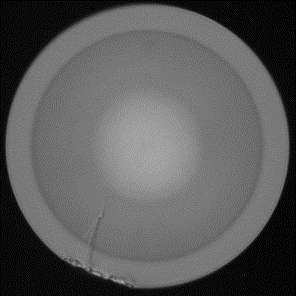

Exail develops diagnostic optical fibers for use in radiation-rich mixed environments typically present in the Megajoule class laser facilities (schema of the CEA-LMJ setup).

Publications

-

Phosphosilicate Multimode Optical Fiber for Sensing and Diagnostics at Inertial Confinement Fusion Facilities

IEEE Sensors Journal ( Volume: 22, Issue: 23, 01 December 2022)

https://ieeexplore.ieee.org/document/9934019