- Photonics & Space

Enhancing the adoption of aluminum-coated optical fibers in the nuclear field

Started in 2021, the 3F2E collaborative project has sought to develop special optical fibers with innovative metallic coatings for sensing applications in nuclear environments, and other harsh environments. Today, Exail announces that it has started to add new references of optical fibers with aluminum coatings to its portfolio, a direct result of the 3F2E project.

Setting up a “100% Made in France” integrated industry of optical fibers with metallic coating for nuclear applications

3F2E for “French Fiber Field for Extreme Environment” is a 100% French collaborative project funded by the post-pandemic France’s economic stimulus plan “Relaunch France” to support investment and strengthen the capabilities of the French nuclear industry. Since 2021, it has aimed at developing radiation-resistant optical fibers, based on the extensive know-how developed by Exail over the last decade, with a metallic coating added by the technology platform Photonics Bretagne, and packaged by SEDI-ATI with seals and protections for nuclear environment use.

The last partners of 3F2E are TechnicAtome and EDF, who represent final users for the integration of the technology into “use cases” close to existing needs. The 3F2E project received the support of some major contractors and agencies in the industry (CEA, CNES, ORANO, ANDRA) intending to set up an integrated French supply chain and guarantee national sovereignty over this strategic technology.

By the end of 2025, new special optical fibers with 3 different types of coatings will have been developed for the nuclear market, and applications in any harsh environment involving high temperature and/or radiation levels:

- aluminum coating,

- carbon and polyimide coating,

- carbon and metallic coating.

“Thanks to a good and efficient collaboration between the different partners, the 3F2E project has already allowed tremendous progress, in particular, many technological hurdles have already been overcome.” expressed Adrien Steib, deputy R&D manager and 3F2E project manager at Exail “We are proud to announce a direct outcome: the first 100% made in France aluminum coated optical fibers are now qualified and available in Exail’s portfolio. It took a year of iterations with partners at the technology platform of Photonics Bretagne to improve the manufacturing process. Stay tuned, as new carbon-coated fibers, currently under development, are due to be released in 2024.”

New rad-hard optical fibers with aluminum coating

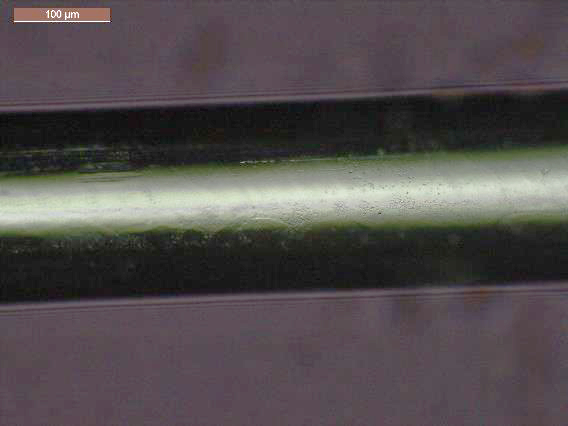

Exail was able to draw the first aluminum-coated optical fibers, a “100% Made in (Brittany) France” product line, together with Photonics Bretagne, and its dedicated fiber-drawing tower. They have obtained very positive results in terms of linear attenuation and mechanical strength “A whole year of development was necessary to perfect the manufacturing process, eventually allowing the successful application of a smooth structureless aluminum coating.” explains Adrien Steib.

Aluminum-coated fibers offer a wide operating temperature range, up to +400°C. They are also hermetic to hydrogen and water vapor, mitigating hydrogen darkening in hydrogen-rich environments. Optical fibers with aluminum coating are well suited to applications in sensing and monitoring, such as Distributed Temperature Sensing (DTS), in nuclear environments, oil and gas, high-energy physics experiments, or space.

“I am delighted to complement Exail’s portfolio of harsh environment fibers with a comprehensive range of aluminum-coated fibers. These singlemode and multimode fibers are ideal for sensing and monitoring in high-temperature environments. Leveraging Exail’s expertise in radiation-hardened fibers, we also offer several Rad-Hard fibers with aluminum coating, something unique in the industry.” Mathieu Bergont, specialty fiber product manager at Exail

Aluminum-coated fibers currently in stock:

|

Exail leverages extensive know-how in designing and manufacturing preforms and radiation-resistant optical fibers (rad-hard, single mode and multi-mode) for use in harsh environments with extreme temperatures and/or low to high radiation levels. They are designed to mitigate the effects of Radiation-Induced Attenuation (RIA) and extend the fiber’s lifetime when used in radiative environments. Exail develops and maintains a comprehensive product line of fibers designed to fit many of such applications: data transmission, sensing, or experiment monitoring.