- Photonics & Space

iXblue extensive components portfolio for 2µm fiber lasers applications

The optical fiber doped with rare-earth elements – the active gain medium – and Bragg gratings – the mirrors of the laser cavity – are key components that iXblue have mastered for many years, especially in the 1,5 µm range. They are being incorporated in a growing number of laser applications: lidars, laser markers, laser cutters, plastic welding, defense lasers and a new sector: lasers for medical purposes. Today, new applications are rising for fiber lasers in the 2 µm range, which has driven recent innovation in specialty fiber technology.

Even if still more expensive than the 1 or 1,5 µm lasers, the 2 µm lasers address “niche” markets but with strong added value. If one of the main advantages of the 2 μm laser is its power, it also has a considerable asset for many applications as it is “eye-safe”, meaning that our eye is sensitive to its beam and instinctively closes itself when touched. That is not the case with thinner laser beam that can reach deep inside our eyes and damage it irreversibly.

The 2 μm laser for LIDAR with applications in defense and environment

The generic term of LIDAR for LIght Detection And Ranging finds its use nowadays in many different systems and applications, from the scanning of surroundings to create a 3D digital map of obstacles (for instance in autonomous driving applications) to atmospheric Lidars that detect gases or aerosol particules (for instance in environmental applications). Another well spread application is the detection of atmospheric turbulences to secure wind-turbines operation or airports. All these systems have different requirements in terms of wavelength, power and pulse profiles.

iXblue offers a wide range of specialty fibers and Electro-Optic Modulators (EOMs) that can answer the various challenges of Lidar applications. Fiber laser sources emitting around 1.5 μm have already shown key advantages in the fields of wind farms and aircraft safety: versatility, modularity, and robustness of alignments to vibrations. The applications opened today for 2μm fiber lasers in defense and atmospheric science represent appealing future markets for iXblue.

The French-German Research Saint-Louis Institute (ISL), at the occasion of a research program with the DGA (French Government Defence procurement and technology agency), has obtained and presented in 2021 some interesting results using an iXblue optic fiber: a monolithic laser source with thulium-holmium co-doped fiber in single oscillator emitting 195 W at 2090 nm in continuous mode (A. Motard and al. Optics Express (2021)).

The 2 μm laser for urology

An interest is rising among medical laser manufacturers for thulium-doped fiber. Laser technologies are used in flexible ureteroscopy, for ureteric and kidney stone management. The goal is to be minimally invasive without breaking the skin barrier. The thulium fiber laser has several advantages over the Holmium YAG laser, traditionally used in urology. With a wavelength of 1940 nm, the absorption coefficient of thulium fiber laser is four times greater in water (1940 nm matches the near-infrared absorption peak of liquid water at room temperature), and it enables much smaller spot sizes to be created with less powerful pulses but at a much higher rate. It has average and peak powers of 100 W and it does not burst tissues, providing clean and precise cutting. It allows for pulse prolongation up to 12 ms, with regular pulses. Therefore, the power produced by the laser has a constant peak, called the super pulse creation. It is perfect for surgical applications, providing even greater precision and less collateral damage.

iXblue has developed a fiber laser cavity (a thulium doped fiber and fiber Bragg gratings – FBG), for this innovative laser technology that may become an important milestone for kidney stone treatment.

iXblue portfolio for 2 µm fiber lasers and FBGs

With its extensive experience and its large fibers and FBG Laser mirrors portfolio, iXblue can support the emergence of innovations in 2 µm fiber lasers. iXblue solutions to reach high-power (around 50 W) lasers but also power scaling in lasers will draw the attention of expert as they are based on proven-and-tested manufacturing processes.

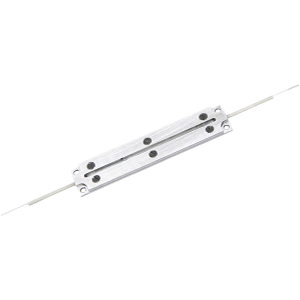

Any small irregularities contained in an optic fiber architecture (especially at the junctions of fibers) can heat rapidly and damage the fiber. Each step of the fabrication process of a FBG must be carefully controlled to avoid these irregularities. The iXblue know-how on special optic fibers is key on this aspect. It led to the development of a specific “HP” process for high-power applications, on top of the already existing expertise in term of excellent matching of (passive/active) optic fibers and in term of packaging for optimal thermal dissipation. The resistance towards heat is increased by a factor 10 with iXblue FBGs compared to the competitors’ solutions.

The doped fibers in the iXblue portfolio especially address the range of 1900 to 2090 nm (i.e 1940 nm for urology, 2036 nm for LIDAR, etc.), with different absorption wavelengths available for the FBGs that can be incorporated to any kind of fiber. Most importantly, iXblue can produce custom fibers based on core co-doped with Thulium (Tm), Holmium (Ho), or both (Tm/Ho), with on demand customization: any core size (4 to 25 µm), one-two or three claddings, any kind of coating (including innovative ones for high temperature or harsh environment) and any kind of doping level. The fiber can also contain a polarization-maintaining (PM).

iXblue provides splicing services for specialty fibers (high power, large diameter, etc.) with adapted recoating and packaging solutions. The resulting sub-assemblies will be validated with a test report for final qualification (efficiency, temperature, …). From its on-the-shelve products up to the most recent generation innovative products, iXblue can answer to its customer needs, even the most exotic ones, with the same quality and reliability: from very short series (several components) to larger volumes (tens to hundreds of components), but always with specific customizations. Parameters that can be adjusted are the wavelength of the filter (between 600 and 2000 nm), the bandwidth of the reflected beam, the level of reflectivity of the FBG, and the spectral shape of the FBG. iXblue can create prototypes that can be industrialized very quickly.

| Doping Materials | |

| Thulium | Single Clad 4 and 5 μm core, PM and non-PM Double Clad 6 to 25 μm core, PM and non-PM |

| Thulium-Holmium | Double Clad 6 to 25 μm core, PM and non-PM Triple Clad 18μm co |

| Holmium | Single Clad 8μm core, PM and non-PM Single Clad 20 μm core, PM Triple Clad 20 μm core |

Matching passive fibers available

Custom versions available

| Fiber Type | Typical available Wavelengths – High Power process |

| 4 to 25μm core Single Clad, Double Clad and Triple Clad PM and non-PM Double C |

1908 – 1940 – 1950 – 2036 – 2050 – 2090 – 2120 |

Other components available at iXblue for 2μm: Lithium Niobate Modulators, Variable Optical Delay Lines, beam splitters, beam combiners

200W Laser cavity with iXblue Thulium double clad Fiber (courtesy of French-German Institut of Saint Louis – ISL)