- Photonics & Space

Enhancing high-energy laser capabilities

Exail’s sub-nanosecond pulse shapers meet all the requirements of demanding high-energy laser facilities.

In the last decades, the United Kingdom government agency “Science and Technology Facilities Council (STFC)” has invested in the development of new laser technologies through its central laser facility (CLF). It has aimed at keeping its laser capability at the international forefront until today, principally through the development of a world leading laser architecture called DiPOLE, a new high-energy, high-repetition rate and high efficiency pulsed laser technology. Being able to generate accurate impulsions with reliability over time is a challenge for such a demanding laser facility. Exail could meet all the requirements with its ModBox Front-End, a versatile sub-nanosecond laser pulse generation transmitter based on unparalleled LiNbO3 modulator design.

The STFC CLF won several contracts in the high-energy field with this new DiPOLE architecture. It includes the construction of the first 100 J / 10 Hz laser system provided for HiLASE Center (see picture below) in Czech Republic, for the development of pulsed nanosecond diode-pumped solid-state laser. A similar system was constructed for the European XFEL in Germany, a large high-energy infrastructure for the generation of extremely intense X-ray flashes. CLF also delivered parts of an amplifier head to ELI (Extreme Light Infrastructure – see cover picture), in Czech Republic, which aims at being the world’s largest and most advanced high-power laser infrastructure.

For all these developments, the STFC CLF works with industrial partners to facilitate solutions to real-world problems. The optical pulse shaping solution of Exail, the “ModBox Front-End”, was selected as an industrial turn-key solution to facilitate the exploitation of such an extensive technology.

DiPOLE, a technological reference in the high-energy laser field

DiPOLE is the first cryogenically gas cooled, diode-pumped, solid-state laser (DPSSL) system, initially conceived as a prototype. The DiPOLE laser architecture provides a scalable concept design for efficient, high-energy, high-repetition rate. This complex technology was proven mature and established as a reference in the field. It relies on an innovative laser diode pumping system and a powerful cryogenic cooling system, based on intense gas bursts. It also has a multi-slab amplifier head. The DiPOLE laser system is designed for operation from 10 Hz to 100 Hz pulse repetition rate, with pulses at high-energy. In comparison, the repetition rate of most high-energy facilities in operation in the world today is often lower than one pulse per minute. Real-world applications exploiting ultra-high intensity light-matter interactions will require development of lasers and technology, capable of operating at high pulse energy and repetition rate.

Currently, DiPOLE features an automatic beam alignment system, an adaptive optic system, and thanks to Exail’s ModBox the ability to easily generate and modify temporal pulse shapes.

The DiPOLE laser during recommissioning at HiLASE / Copyright CLF

Reaching state of the art temporal pulse shaping performance using ModBox Front-End

Exail’s ModBox Front-End was selected as a solution in the DIPOLE laser architecture. It is used for the optical shaping of the initial laser impulsion, which is amplified a billion times within the system, from several nJ to 150 J. The ModBox offers accurate control of the temporal shaping of each laser impulsion, with its capability to correct the pulse characteristics even at high-repetition rate. It is a crucial tool to optimize the performance of a high-energy laser facility. “The stability, the reproducibility and the quality of the impulsions generated by the ModBox were some of the most important criteria in the strict specifications of STFC, as well as the reliability over a period of several months” explains Alexandre Soujaeff, ModBox Business Engineer at Exail.

The ModBox Front-End selected to equip the DIPOLE laser systems is an industrial turnkey system, based on Exail’s unique know-how in designing and manufacturing LiNbO3 modulation solutions. The company has built up a strong experience in such systems and successfully installed them in many research laboratories over the world, and in industrial companies.

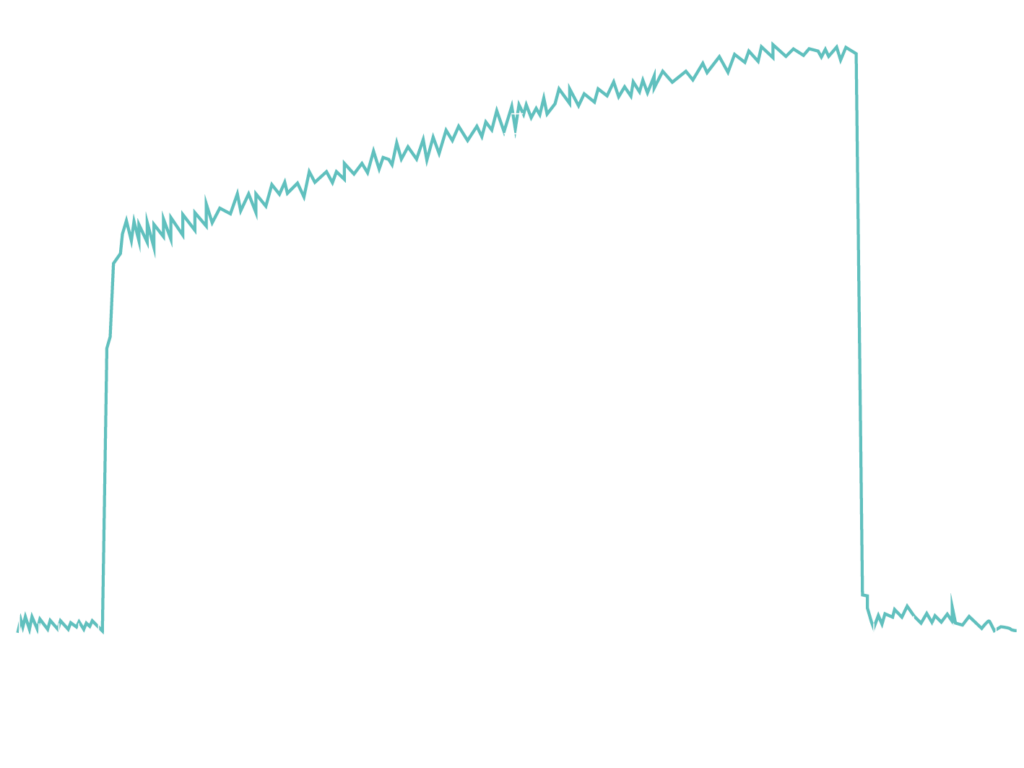

Exail know-how in the modelization of complex electro-optic system in the RF domain enables advanced correction capability (see experimental curve). With this feature, ModBox users can easily perform pulse shaping with a high level of fidelity.

Exail indeed masters all three key components needed for optical pulse shaping application: the Electro-Optical Modulator (EOM) based on lithium niobate technology, the high speed and high voltage linear driver for EOM modulators and the modulator bias control (MBC) board.

Each new customer request and each new challenge has led to an improvement of Exail expertise, leading to the most recent products currently in the company portfolio. The ModBox-FrontEnd is challenging the state of the art of temporal pulse shaping performance, as Alexandre Soujaeff, describes it: “With the ModBox FE we are able to generate laser pulses with any kind of temporal shape. And compared with a simple modulation solution, an integrated ModBox solution offers unique performance in term of contrast and stability”.