LabH6: Custom Optical fibers for challenging radiative environment

Some examples of new specialty optical fibers

TOWARDS DISCRIMINATED AND DISTRIBUTED TEMPERATURE AND STRAIN MEASUREMENTS

Different applications require the development of dedicated optical fibers. Those fibers must then have their optical properties optimized for the intended application, obtained by working on their refractive index profiles and/or compositions. As an example, it is well known that the Brillouin signature of fibers depends on both the temperature and strain applied on it.

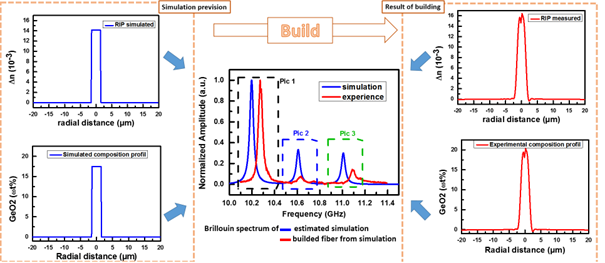

A dedicated specialty fiber has been developed to allow discriminated measurements of these two parameters by a distributed sensor based on Brillouin backscattering. Fig.1 illustrates the coupled ‘simulations and experiments’ approach followed to design this new optical fiber [C. Sabatier et al., J. Lightw. Techn., 2019]. Multi-physics simulation tools have been developed and validated (in collaboration with Politecnico di Bari). They make it possible to model the fiber Brillouin signature knowing its composition and refractive index profile (PhD thesis UJM/iXblue).

These results are then used to design and evaluate the potential of different fiber structures in terms of discrimination. The most promising ones were then manufactured at iXblue by MCVD process and characterized at LabHC. The current generation of this specialty fiber is able, using a commercial interrogator, to discriminate the temperature and strain variations with a metric spatial resolution and uncertainty accuracies of 1°C and 25 με [C. Sabatier, Thèse de doctorat, 2019].

THE LabH6 PARADIGM SHIFT

Design a hardened fiber rather than harden a specific fiber

iXblue’s specialty optical fiber design and development methods combined with the expertise of the Hubert Curien laboratory in the field of silicate material responses in a radiation environment allow to address, from the design phase, the possible vulnerability issues related to the operation in harsh environments. During the last years, this approach has been successfully tested in partnership with numerous research and industrial institutes such as ANDRA, EDF R&D, CERN, CEA, Siemens, Orano …

Fiber optics for MegaJoule lasers

Optical fibers are a key element of laser diagnostics (operating at 351 nm) or plasma diagnostics (visible range) of facilities devoted to the study of inertial confinement fusion: Laser Megajoule (France), National Ignition Facility (USA) [J. L. Bourgade et al., Rev. Sci. Instr., 2008]. In particular, the fibers of the laser diagnostics must have very specific properties to ensure the proper characterization of the beams focused on the cryogenic target. Their optical losses must be less than 0.2 dB/m (theoretical limit at 0.08 dB/m) and their temporal dispersion less than ps/m at 351 nm.

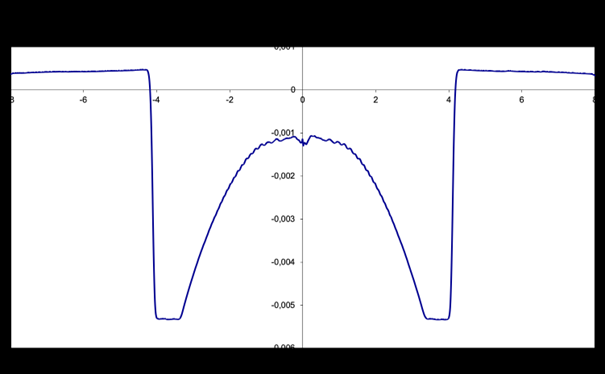

These multimode fibers must also have a large core (> 100 µm) and their inter-modal dispersion control requires a parabolic gradient refractive index profile. Ideally, they should also withstand the permanent effects of an irradiation pulse combining ‘X, ɣ and 14 MeV neutrons, typical of fusion experiments [S. Girard et al., IEEE TNS, 2006]. Such optical fibers have been developed by iXblue, using their R&D tools (Fig.2). The different generations of this category of optical fibers were then characterized under irradiation by the LabH6 in the framework of a collaboration with the CEA DAM centers: CESTA and DIF. Fig.3 illustrates the parabolic refractive index profile of an optical fiber having a fluorine-doped silica core, making it possible to reach the desired optical performances (attenuation, dispersion) at 351 nm.

- Optical fibers with low UV attenuation and radiation-resistant are available: Custom Fibers